TECHNICAL KNOW HOW

The technical know how for a turnkey capsule manufacturing project consists of• Layout as per WHO cGMP guidelines

• Suggestions for all equipment & specifications & vendors thereof

• Assistance in ordering & testing with dry runs of all equipment

• Project management & monitoring

• Co-ordination with various agencies hired by the client, .. like civil, electrical, plumbing, air-conditioning, etc

• Erection, testing & commissioning of all equipments in .. coordination with respective suppliers

• Training of manpower with SOPs

• Specification & selection of manpower

• Post implementation consulting if required

TOTAL EQUIPMENT

The equipment for a capsule manufacturing plant will consist of the following:

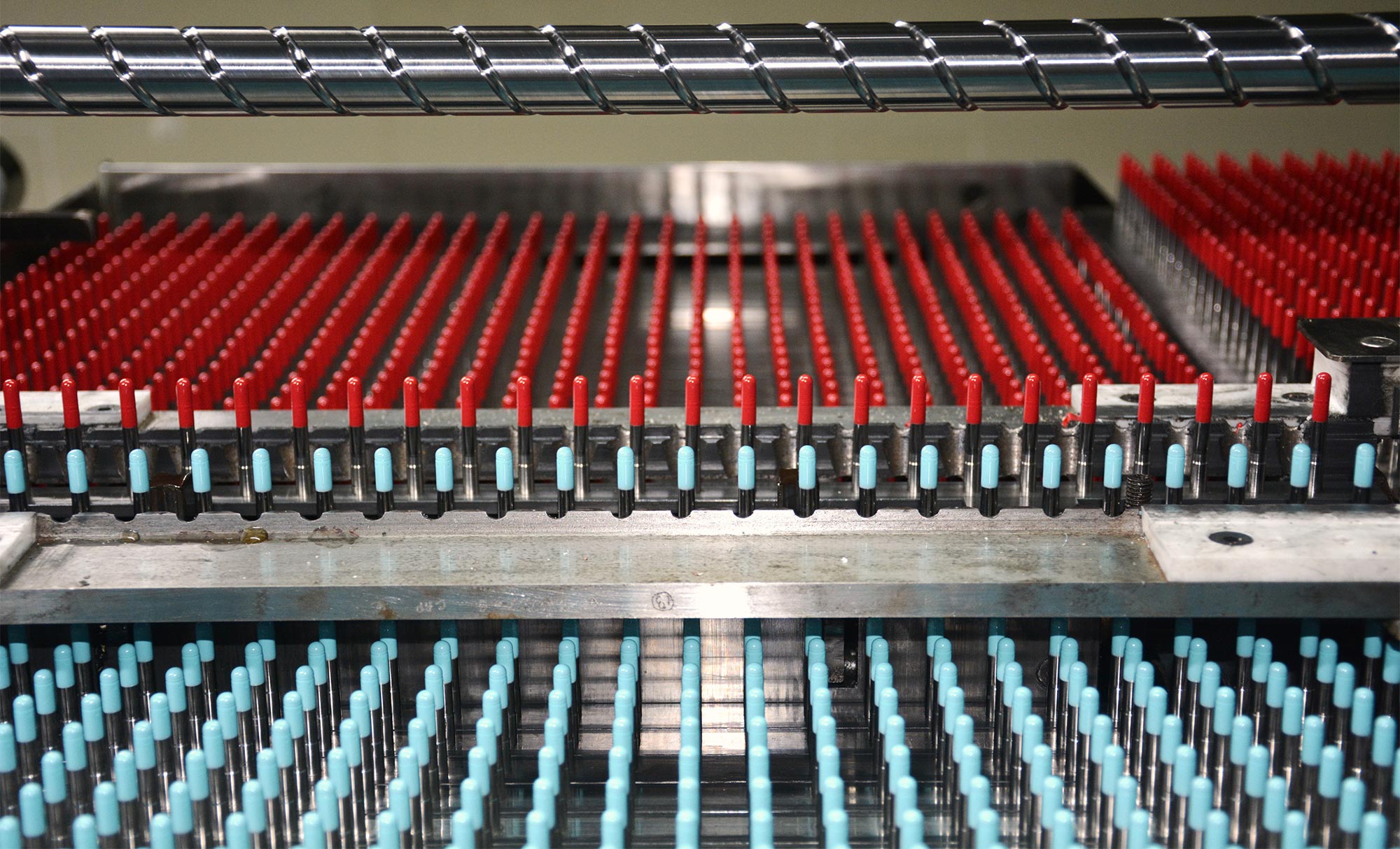

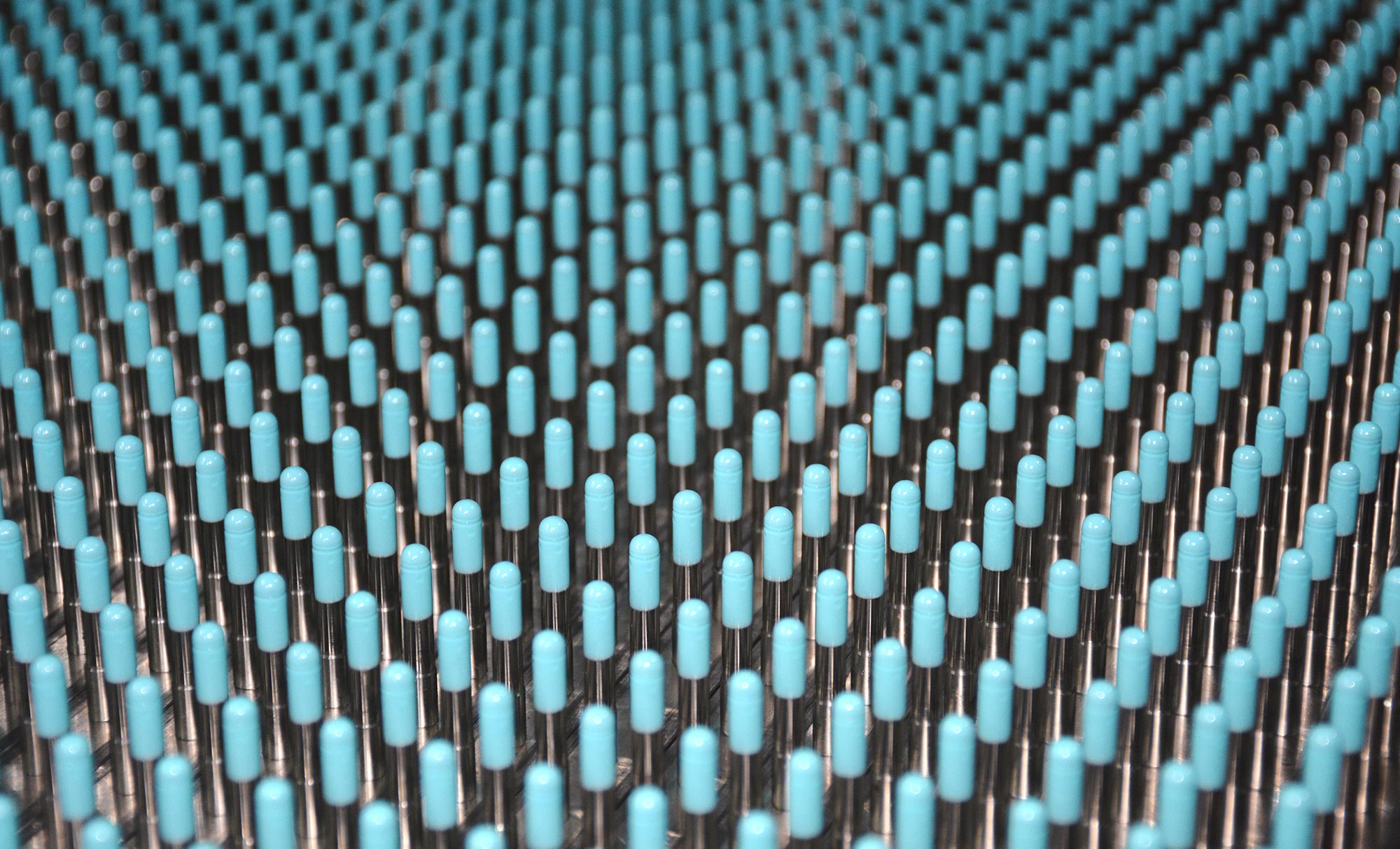

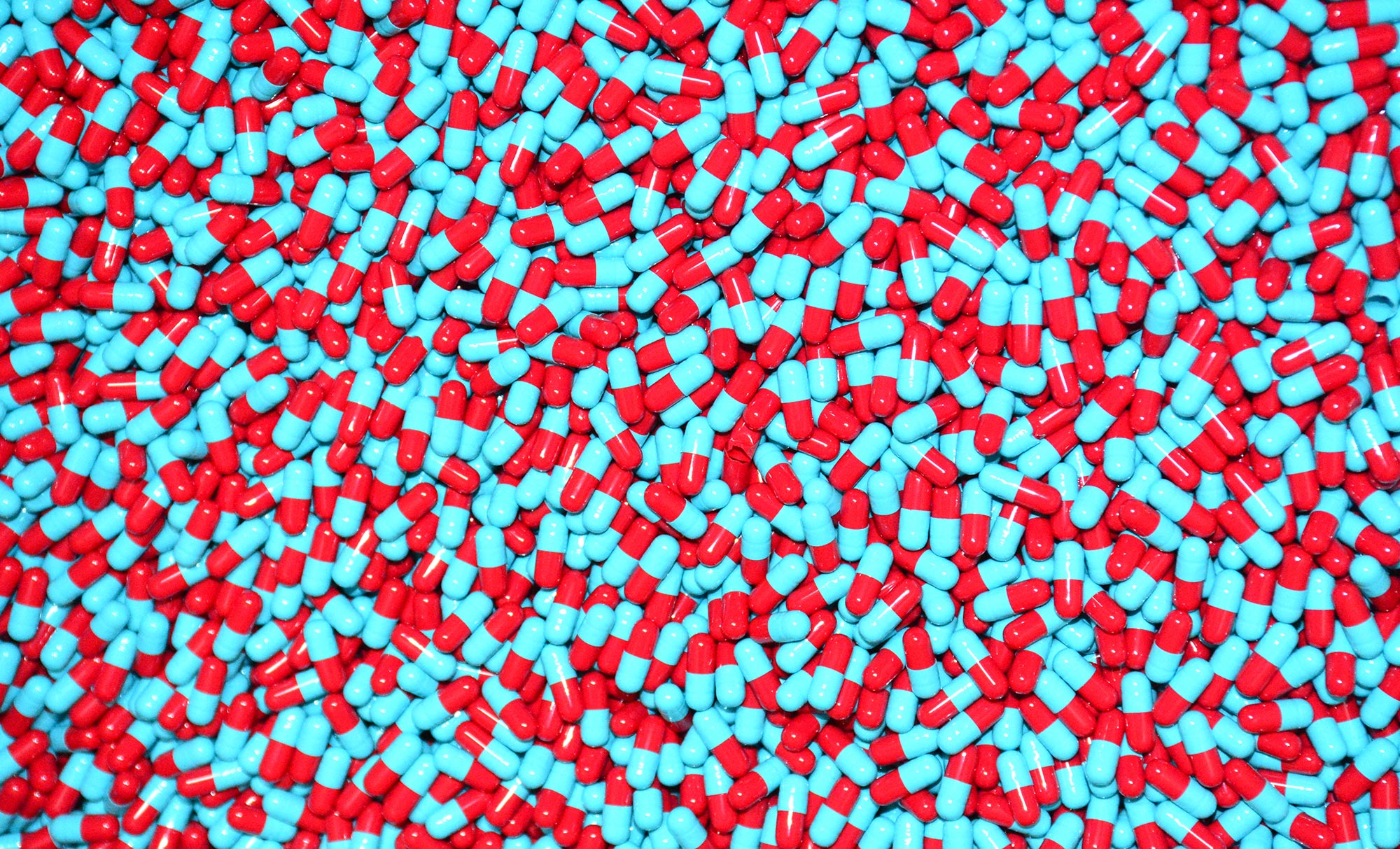

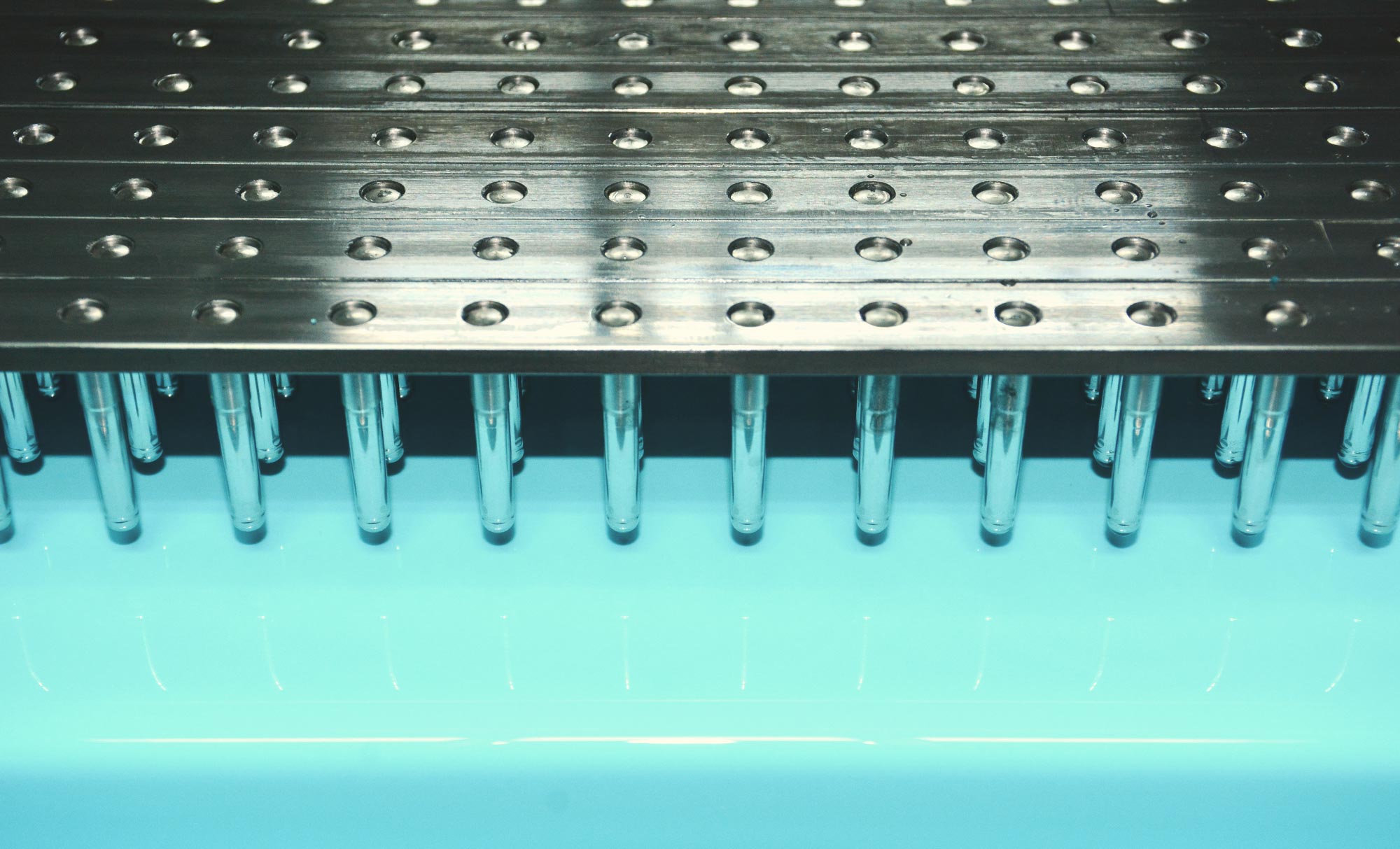

• Capsule making machine

• Pin Bars

• SS Drying Hoods

• Cyclones

• Control Panel

• Viscometer

• Moisture Meter

• Gauges

• Melter Mixer

• Capsule Printing Machine

• Sorting Tables

• Jigs & Fixtures

• Pin Bars

• SS Drying Hoods

• Cyclones

• Control Panel

• Viscometer

• Moisture Meter

• Gauges

• Melter Mixer

• Capsule Printing Machine

• Sorting Tables

• Jigs & Fixtures

• Spares

• Holding Tanks

• Trolleys

• Vacuum Pump

• Compressor

• Colour Mixer

• High Speed Mixer

• Gel Room Items

• Air conditioning Plant

• Laboratory equipment

• Computerized process control

• Miscellaneous other items

• Holding Tanks

• Trolleys

• Vacuum Pump

• Compressor

• Colour Mixer

• High Speed Mixer

• Gel Room Items

• Air conditioning Plant

• Laboratory equipment

• Computerized process control

• Miscellaneous other items

TECHNOLOGY TRANSFER AND TRAINING

•In depth training in operation of hard capsule equipment• Training on all Vegetarian-HPMC-Capsule-Technology equipment

• Integration of all plant departments to generate and maintain ideal production conditions

• Providing in depth understanding of factors affecting capsule quality

• Technology for producing good quality capsules

• Maintenance and trouble shooting training

• Maintenance charts for preventive maintenance

• Trouble shooting manuals