We at Safrroys continuously develop and upgrade our machines and technology so that our end customer is able to produce best quality and maximum quantity of capsules with minimum effort. Click on links below for more details:

CAPSULE MAKING MACHINE

1. Our machines are designed for non-stop, continuous operation with minimal external intervention

2. All machine movements are executed using high precision components and servo motors

3. Ease of operation since timings are always maintained

4. Options of 9 bar dipping with 36/48 bars on table, 7 bar dipping with 28/36 bars on table and 6 bar dipping with 24 bars on table

5. Safeties are included in all critical areas of the capsule making machine to diagnose any problems and prevent accidents

6. Energy saving equipment are incorporated for the lowest power consumption

7. The Smart Start feature results in machine starting up slowly and then quickly coming to running speed which prevents sudden high load on components and thereby increases life

8. An Inching feature is also provided whereby the machine timings can be set and checked at very slow speeds by the operator

9. The entire operation of the machine, safeties, process parameters etc is controlled by a Programmable Logic Control (PLC)

10. Machine operations can be immediately accessed via a touch screen user interface (HMI) mounted on the machine. Recipes can be saved in this HMI for future use. Automatic tamper proof printouts is also possible to meet FDA requirements

11. Safrroys also provides specially developed SCADA Capsule Process Software to continuously monitor, control and record both the machine as well as the process parameters. This is unique to our machines and simplifies capsule production. The data collected is Tamper-proof to meet FDA requirements

2. Extremely high output of up to 160,000 high quality capsules per hour

3. Very high precision Servo motors used in all areas of the machine

4. This system provides complete flexibility to the operator to make adjustments as required to achieve the required quality parameters

5. Specially developed features, unique only to Safrroys XAL-2A, to minimize machine down time even for routine maintenance and thereby increase throughput

2. Machine capable of producing up to 100,000 capsules per hour

3. Safeties are included in all critical areas of the capsule making machine to diagnose any problems and prevent accidents

4. The entire operation of the machine, with safeties, process parameters etc is controlled by a Programmable Logic Control (PLC)

5. Machine operations can be immediately accessed via a touch screen user interface mounted on the machine

6. Latest and best of technology for both hardware and software has been made use of in this machine, enabling production at quantities and quality that is unbeatable

2. Capsule production rate of up to 90,000 capsules per hour, depending on customer needs

3. High levels of customization are possible to meet specific customer requirements

4. High precision servo motors are used for all movements

5. Unique power saving system available as part of complete technology transfer

2. Incorporates all the essential features required for Hard Capsule production

3. Output of 65,000 capsules per hour

4. Cost reduction achieved without any compromise on the quality or long term life of the machine

CAPSULE MAKING MACHINE

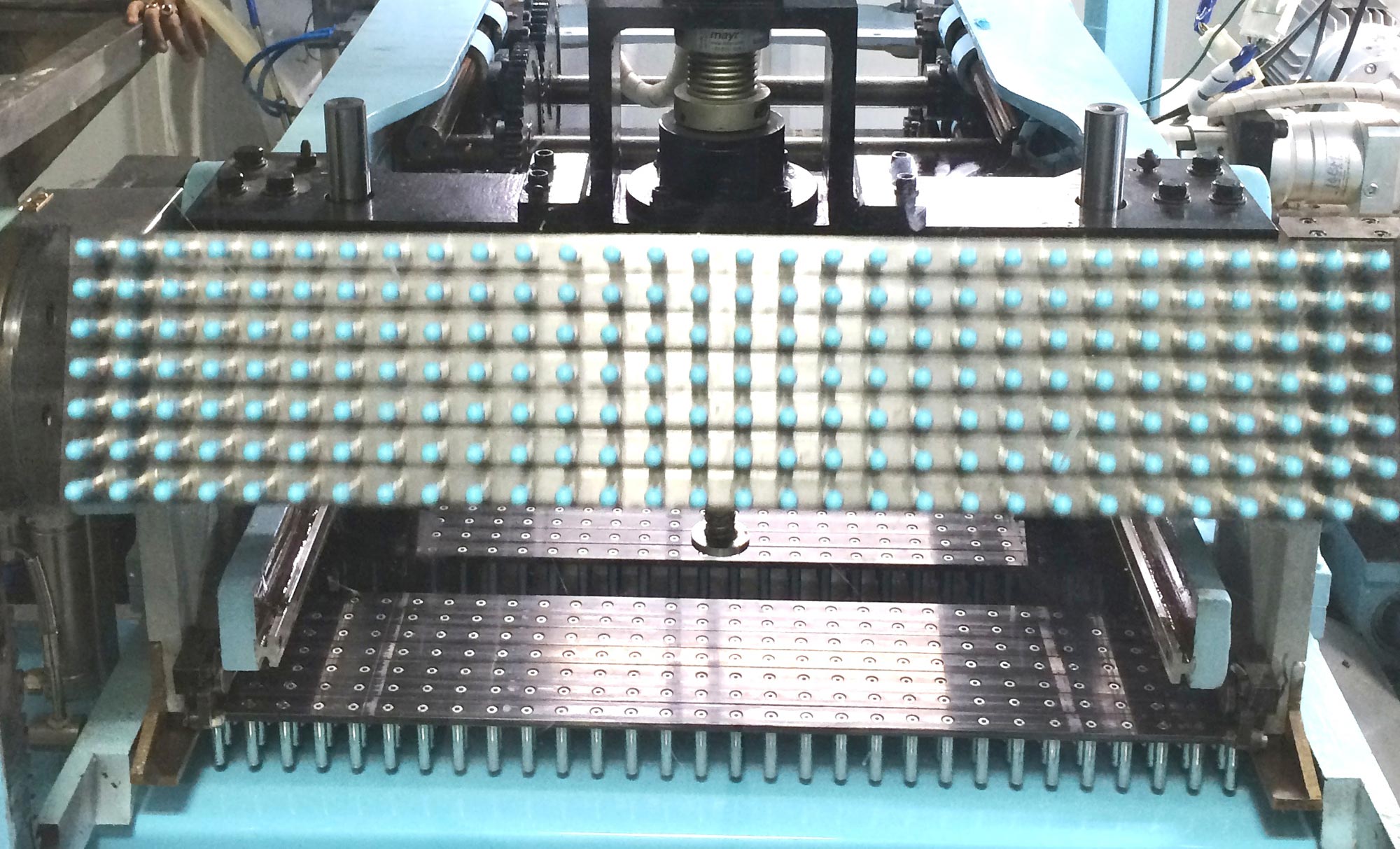

Safrroys Hard Capsule Machines are the result of decades or research and hard work. They have been designed with in-depth understanding of both machine design and assembly as well as hard capsule manufacturing, resulting in the most efficient, technologically advanced machine. All our machine models come with the following unique features

1. Our machines are designed for non-stop, continuous operation with minimal external intervention

2. All machine movements are executed using high precision components and servo motors

3. Ease of operation since timings are always maintained

4. Options of 9 bar dipping with 36/48 bars on table, 7 bar dipping with 28/36 bars on table and 6 bar dipping with 24 bars on table

5. Safeties are included in all critical areas of the capsule making machine to diagnose any problems and prevent accidents

6. Energy saving equipment are incorporated for the lowest power consumption

7. The Smart Start feature results in machine starting up slowly and then quickly coming to running speed which prevents sudden high load on components and thereby increases life

8. An Inching feature is also provided whereby the machine timings can be set and checked at very slow speeds by the operator

9. The entire operation of the machine, safeties, process parameters etc is controlled by a Programmable Logic Control (PLC)

10. Machine operations can be immediately accessed via a touch screen user interface (HMI) mounted on the machine. Recipes can be saved in this HMI for future use. Automatic tamper proof printouts is also possible to meet FDA requirements

11. Safrroys also provides specially developed SCADA Capsule Process Software to continuously monitor, control and record both the machine as well as the process parameters. This is unique to our machines and simplifies capsule production. The data collected is Tamper-proof to meet FDA requirements

SFR XAL-2A

1. Latest series launched by Safrroys2. Extremely high output of up to 160,000 high quality capsules per hour

3. Very high precision Servo motors used in all areas of the machine

4. This system provides complete flexibility to the operator to make adjustments as required to achieve the required quality parameters

5. Specially developed features, unique only to Safrroys XAL-2A, to minimize machine down time even for routine maintenance and thereby increase throughput

SFR XAL

1. The best selling Capsule making machine globally in the last decade in the international market. Proven technology resulting in consistent high quality capsule production2. Machine capable of producing up to 100,000 capsules per hour

3. Safeties are included in all critical areas of the capsule making machine to diagnose any problems and prevent accidents

4. The entire operation of the machine, with safeties, process parameters etc is controlled by a Programmable Logic Control (PLC)

5. Machine operations can be immediately accessed via a touch screen user interface mounted on the machine

6. Latest and best of technology for both hardware and software has been made use of in this machine, enabling production at quantities and quality that is unbeatable

SFR 901 XAL-V

1. This model of machine has been specially designed to produce HPMC/Cellulose capsules2. Capsule production rate of up to 90,000 capsules per hour, depending on customer needs

3. High levels of customization are possible to meet specific customer requirements

4. High precision servo motors are used for all movements

5. Unique power saving system available as part of complete technology transfer

SFR XAL-Ecoline

1. Most economical model of machine launched by Safrroys2. Incorporates all the essential features required for Hard Capsule production

3. Output of 65,000 capsules per hour

4. Cost reduction achieved without any compromise on the quality or long term life of the machine